Analysis of the Advantages of Light Vehicle Temporary Road Plate and Light Vehicle Temporary Road Mat

972temporary road mats

View detailsSearch the whole station HDPE ground protection mats Video 产品分类菜单

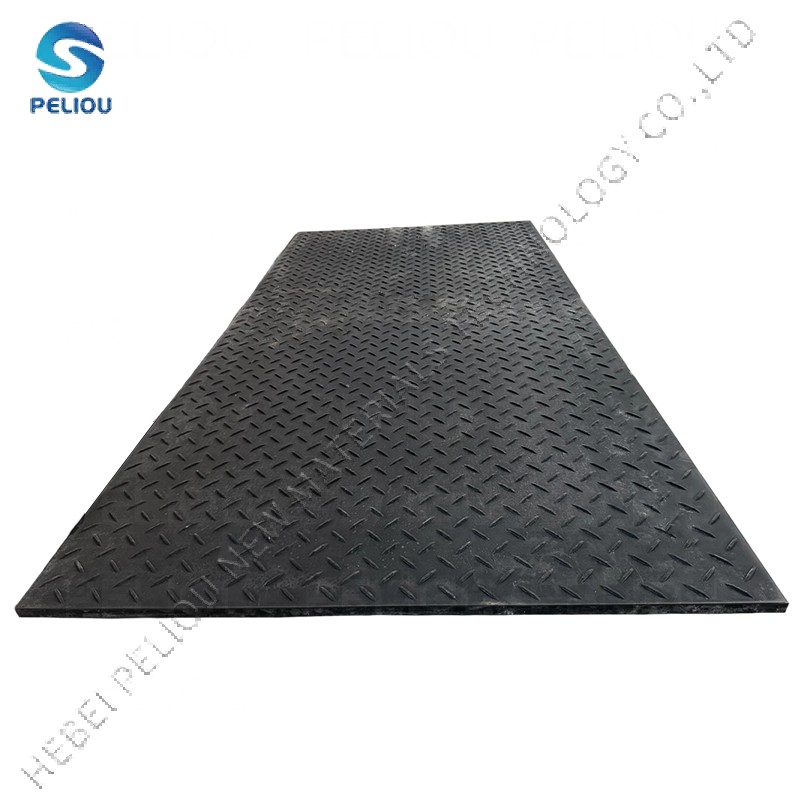

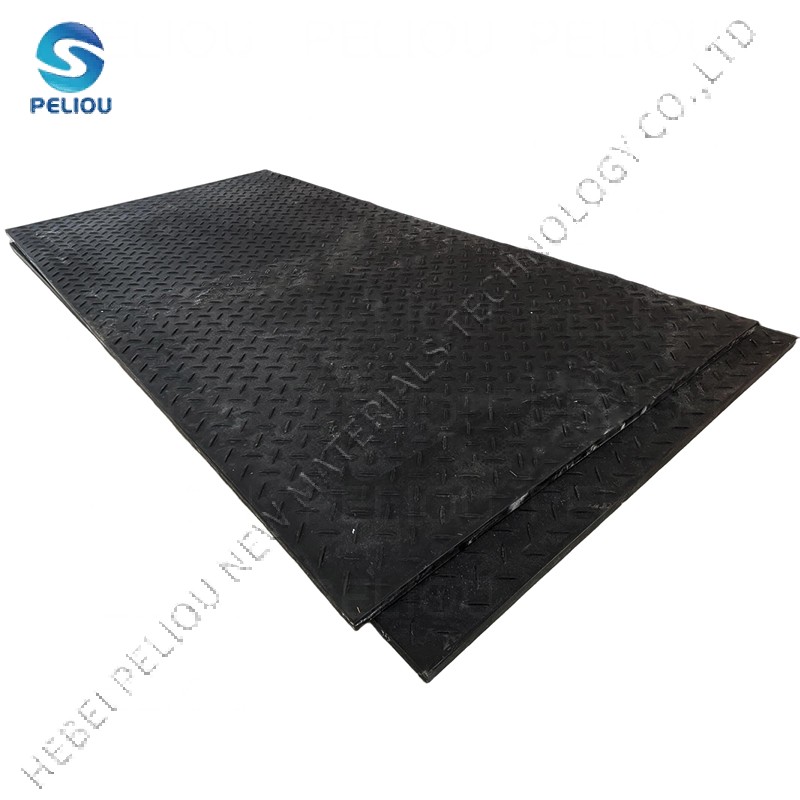

Heavy-duty UHMWPE (Ultra High Molecular Weight Polyethylene) road mats are a high-performance temporary pathway solution, designed for use in extreme and demanding conditions where ordinary mats fall short.

In simple terms, when the work site faces extreme wetness and softness, significant load-bearing pressure, and stringent requirements for equipment protection and long-term durability, heavy-duty UHMWPE road mats are used.

The following is a detailed analysis of the usage and reasons:

Deep muddy ground: At construction sites in marshy areas or after rain, the ground transforms into a bottomless quagmire, where ordinary steel plates or wooden boards quickly sink and are engulfed. Heavy-duty UHMWPE mats, with their extremely high strength and low water absorption rate, can float on the muddy surface, distribute pressure, and create a stable working platform.

Wet and soft wetlands and swamps: For environmental protection, laying of oil and gas pipelines, construction of power facilities, etc., which require crossing ecologically fragile wetlands, materials with low ground pressure and corrosion resistance must be used.

Soft sand: When working in the desert or on the beach, the sand lacks bearing capacity, making heavy equipment prone to sinking.

Carrying super-heavy equipment

Crane operations (especially crawler cranes): When lifting thousands of tons of heavy objects, the pressure exerted by crawler cranes on the ground is immense. Heavy-duty UHMWPE pads are laid beneath the crane’s crawlers, forming a sturdy foundation to prevent the crane from overturning or sinking during operations.

Large mining machinery, such as mining dump trucks and large excavators, have astonishing self-weight and load capacity, necessitating special access guarantees.

Oil and gas fields and wind power projects: Temporary roads for transportation vehicles carrying overweight and oversized components such as wind turbine blades, towers, and transformers.

In situations where there are stringent requirements for ground protection and equipment protection

Paved roads/bridges: When temporary passage of heavy equipment is required, UHMWPE pads are laid to protect the expensive asphalt or concrete pavement from being damaged by caterpillar tracks or heavy tires. Its high wear resistance and smooth surface prevent damage to the pavement.

Indoor venue/warehouse floor: Protect the concrete floor during the assembly or movement of heavy equipment indoors.

Track protection for equipment: The low friction coefficient of UHMWPE means that the track experiences less resistance when turning on the pad, effectively reducing track wear and the phenomenon of “rail gnawing” and extending the track’s lifespan.

ground mats for heavy equipment

View detailsHDPE Road Mats (also commonly called Construction Mats, Access Mats, or Temporary Road Mats) are large, mats made from High-Density Polyethylene. They are a modern, durable, and versatile soluti...

View detailsTransportation not only speeds up people's walking speed, but also increases the speed of human civilization exchange

View details

I loved as much as you will receive carried out right here.

The sketch is attractive, your authored subject matter stylish.

nonetheless, you command get bought an nervousness over that you wish be delivering the following.

unwell unquestionably come more formerly again since exactly the same nearly a lot often inside

case you shield this hike.

Here is my web site: 팔팔정

2026-02-27下午4:20